Scarf Manufacturer

In China

Increase your brand value with our Screen printing scarves, made with high quality.

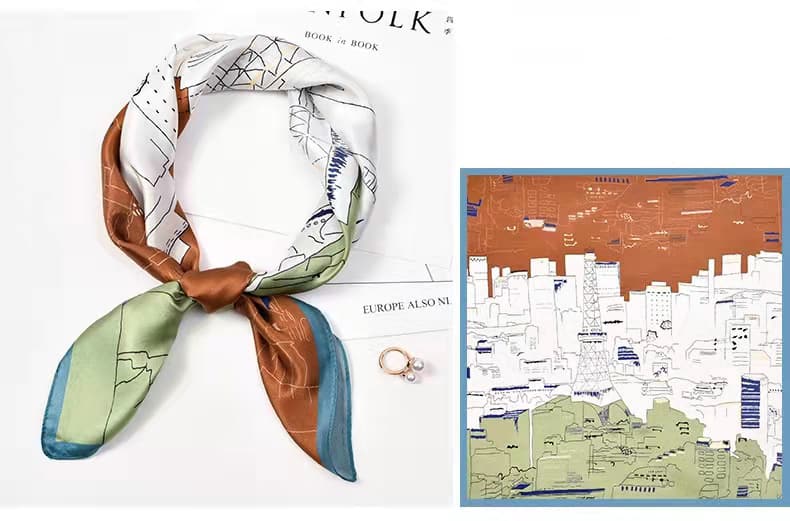

Get Inspired

If you’re on the hunt for fresh ideas on how to convert your entire art into a wearable piece, or if you’re uncertain whether scarves are the ideal choice for showcasing your artwork, here are some renowned and widely admired examples to spark your creativity. *Artwork Requirement

12 Steps !to Scarf Manufacturer Production

- STEP 1

Scarf Fabric Excellence

In our quest to deliver unparalleled quality in scarf Manufacturer, we entrust our raw material procurement to a highly skilled professional. This individual’s role is pivotal.

They have a discerning eye for excellence and a wealth of experience in selecting the finest fibers. Their day-to-day responsibilities involve rigorous assessment and meticulous choice of materials.

- STEP 2

Fabric Coating

Before a single drop of ink graces the material, each scarf fabric is meticulously coated with a clear, protective layer as a primer, optimizing the fabric’s surface for ink adhesion.

This preparatory phase is essential to secure a robust color attachment, ensuring that each hue and shade displayed on the fabric is vivid and enduring.

- STEP 3

Color Harmonization

Our scarf production process begins with a meticulous color preparation stage.

Here, expert toning agents calibrate colors, creating a range of swatches to ensure the shade on the final scarf is the exact match to your specifications.

- STEP 4

Pattern Printing

Our scarf production harnesses high-speed printers paired with premium, imported eco-friendly inks, all orchestrated by advanced computer systems.

This fusion of technology and quality materials forms the core of our printing prowess.

- STEP 5

Fabric Steaming

Each scarf, post-printing, undergoes a steaming process to bring out the vibrancy of the colors.

The steam treatment, a crucial step in our manufacturing, ensures that the hues emerge more vivid and dynamic.

It’s through this careful treatment that the essence of the design is truly brought to life.

- STEP 6

Fabric Washing

The final stage in our scarf fabrication is the washing process, designed to cleanse any residual ink from the fabric.

This crucial step not only purifies the material but also significantly enhances the color fastness.

- STEP 7

Half Check

Post-printing, every meter of fabric destined for our scarves undergoes a meticulous inspection process.

This rigorous quality control ensures that each segment of the material meets our high standards before it moves to the next stage of scarf production.

- STEP 8

Cut the Scarf

In crafting our scarves, we employ a unique cutting method using heated iron wire.

This technique offers a swift yet precise approach, ensuring each scarf is cut to exact dimensions with clean, crisp edges.

The heated wire slices through the fabric seamlessly, minimizing fraying and maintaining the integrity of the material.

- STEP 9

Hand Hemming

Our scarves feature exquisitely finished hems, meticulously hand-rolled by our skilled craftsmen.

For those preferring a more modern finish, we also offer machine stitching as an alternative.

- STEP 10

Professional Ironing

Each of our scarves is expertly ironed using professional ironing machines.

This crucial step ensures that the scarf you receive is perfectly flat, free from any creases or wrinkles.

The meticulous ironing not only enhances the scarf’s appearance but also highlights the quality and texture of the fabric.

- STEP 11

Check the Scarf

Every scarf undergoes a thorough inspection, with a double-check process in place to minimize the defective rate.

This ensures that each scarf meets our stringent quality standards, guaranteeing customer satisfaction.

- STEP 12

Scarf Packing

For our scarves, we offer customizable inner packing to suit your preferences.

The outer packing involves a sturdy carton, ensuring that the scarf reaches you in complete and pristine condition.

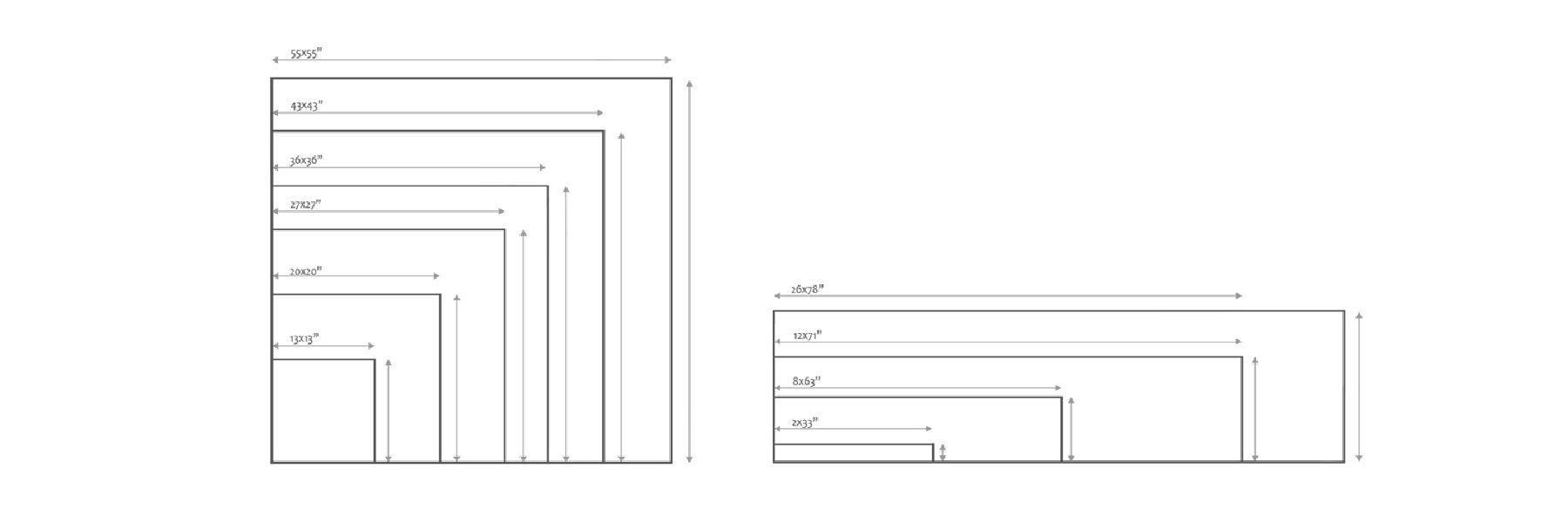

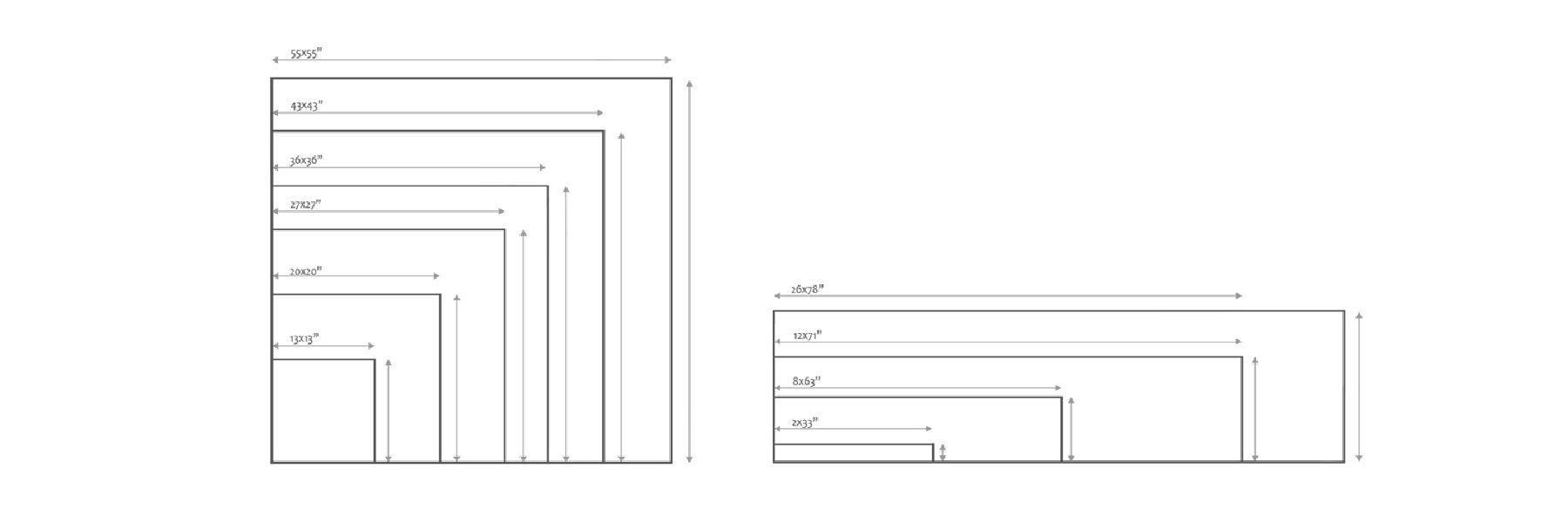

Choose popular sizes

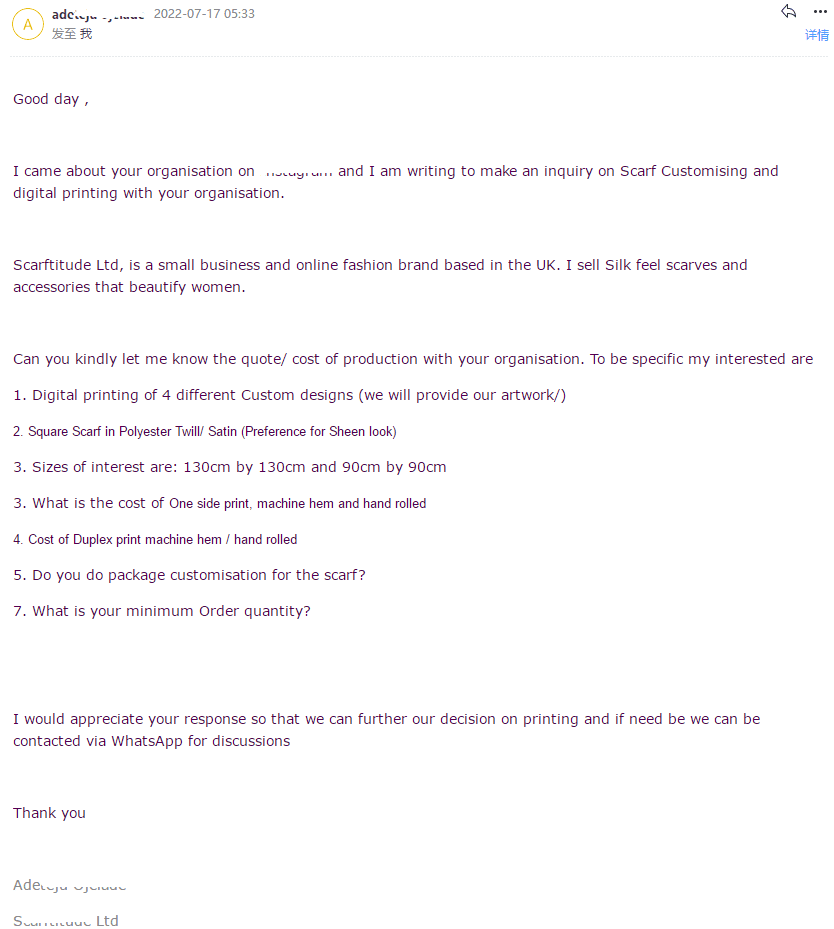

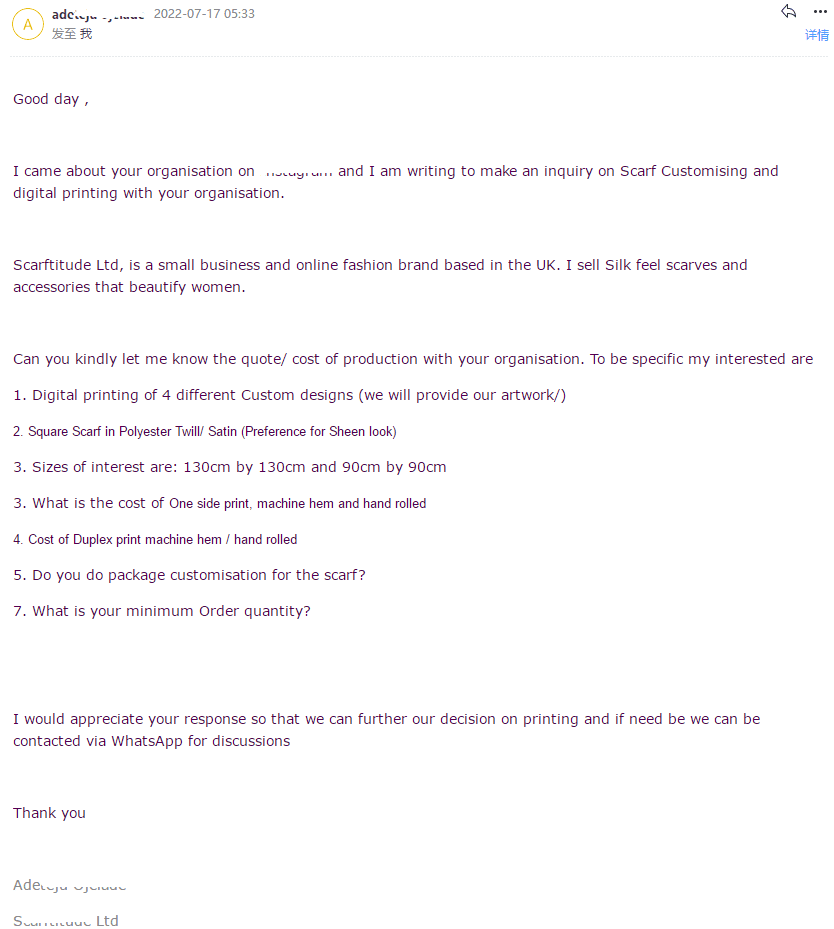

From Ade UK - Frist Email

From Ade UK - Last Email

About this projcet for Ade UK

I was pleased to work for Ade from the UK on this custom scarf project. We exchanged three or four emails and the project was confirmed. 😃

After more than half a month, Ade got his artwork finished scarf smoothly and happily.

Seeing Ade’s satisfaction, I felt happier myself. 😁

About custom scarf for Ade UK

Craftsmanship Meets

Strict Quality Control

When artisanal craftsmanship meets strict quality control, the result is create scarves of consistent top quality.

At SCARF.COM, our create scarves makers boast at least 10 years of experience. Combining the traditional art of fashion scarf making, they create fashion scarf of meticulously handcrafted quality.

In the quest for excellence, we apply strict quality control in our factory. Our in-process & final product inspections further ensure uniform colors, shapes, sizes & quality.

Full Service

From Concept To Launch

At SCARF.COM, our collaboration goes beyond product design & manufacturing.

From before-sales guidance to after-sales support, we’ll walk you through the whole process of creating your custom fashion lines.

By working with us, you can:

Our Past Successes

In the past decade, we’ve delivered custom create scarves solutions to the top names in the fashion industry.